|

MODEL |

JTST-D49 |

JTST-D80 |

JTST-D120 |

JTST-D216 |

JTST-D1000 |

|

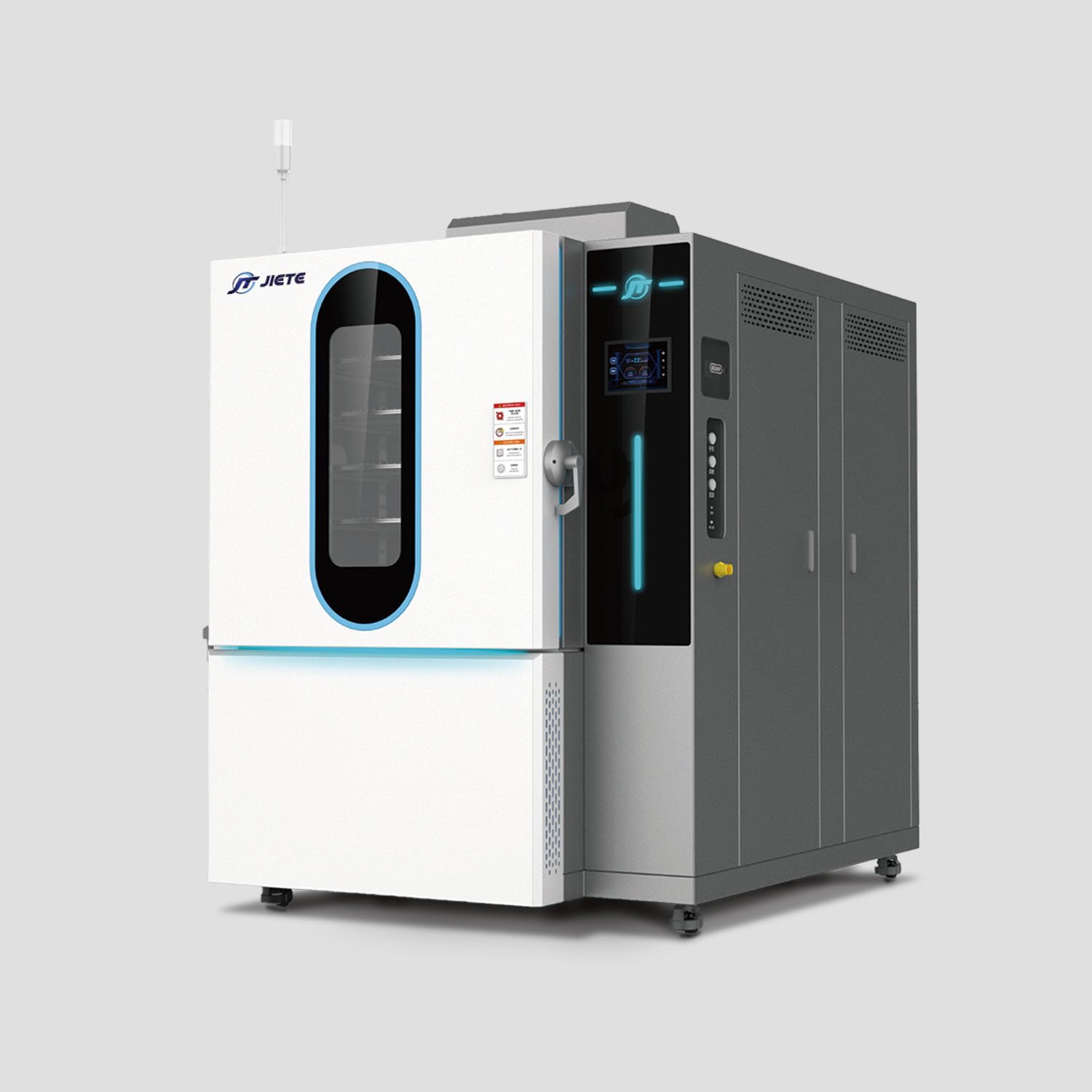

Chamber Design |

|

Basket Capacity |

L |

49 |

80 |

120 |

216 |

1000 |

|

Internal

Dimensions (cm) |

W |

40 |

50 |

60 |

60 |

100 |

|

H |

35 |

40 |

40 |

60 |

100 |

|

D |

35 |

40 |

50 |

60 |

100 |

|

External

Dimensions (cm) |

W |

133 |

143 |

153 |

153 |

295 |

|

H |

200 |

205 |

205 |

225 |

250 |

|

D |

182 |

65 |

197 |

207 |

201 |

|

Temperature Test Parameters |

|

Temperature

Range |

°C |

-70℃~180℃ |

|

Temperature Shock Range - High Temperature |

°C |

+60℃~+150℃ |

|

Temperature Shock Range - Low Temperature |

°C |

-65℃~-10℃ |

|

Heating Rate - Hot Zone |

Room temperature →+180 ℃ ≤ 30min |

|

Cooling Rate - Cold Zone |

Room temperature → -70 ℃ ≤ 60 minutes |

|

Impact Method |

Two vertical zones |

Two horizontal zones |

|

Conversion Method |

Vertical movement of the basket up and down |

Move the basket horizontally left and right |

|

Temperature Fluctuation |

°C |

±0.5℃ |

±0.5℃ |

±0.5℃ |

±0.5℃ |

±0.5℃ |

|

Temperature Uniformity |

°C |

2.0℃ |

2.0℃ |

2.0℃ |

2.0℃ |

2.0℃ |

|

Conversion Time |

sec |

Basket conversion time ≤ 10 s, temperature conversion time ≤ 300 s |

|

Power Supply And Connection |

|

Rated Voltage |

V/Hz |

AC380V 50Hz |

|

Maximum Current |

A |

36.5 |

39.5 |

53.2 |

68.4 |

100 |

|

Maximum Power |

KW |

24 |

26 |

35 |

45 |

65 |

|

Control Mode |

PID+SSR |

|

Environmental Temperature/Humidity For Use |

A air-cooled (ambient temperature: 5 ℃~28 ℃)/W water-cooled (water temperature: 10 ℃~28 ℃, water pressure: 0.25~0.4MPa) |

|

System Components |

|

Material Science |

Shell Material |

Electrolytic board baking paint, thickness 1.5mm |

|

Inner Liner Material |

Stainless steel plate SUS # 304 (cold and heat resistant, first-class glossy panel, thickness 1.0mm) |

|

Thermal Insulation Material |

High density rock wool+high temperature resistant high-density polyurethane foam |

|

Refrigeration System |

Cooling Method |

Mechanical binary freezing method (air-cooled/water-cooled) |

|

Compressor |

Grain Wheel Vortex Compressor/German Bitzer Semi Enclosed Type |

|

Refrigerant |

High-temperature machine: R404A (with an ozone depletion index of 0);

Low-temperature machine: R23 (with an ozone depletion index of 0) |

|

Heating System |

Nickel chromium alloy electric wire heater |

|

Circulating Fan |

High temperature exposure: free; Low temperature exposure: Off frequency type |

|

Door Observation Window |

The door is equipped with a 3-layer vacuum glass observation window for heat and sweat prevention;

Door frame electric heating (automatic adjustment) anti frost and anti condensation device |

|

Temperature Sensor |

Platinum resistance PT100 |

|

Temperature Controller |

Touch screen input+TFT color LCD display |

|

Noise |

dB(A) |

≤ 75dB (A-level sound level) |

|

Safety Device |

Overtemperature protection, compressor overpressure, overload protection, fan overload protection, leakage protection, etc |