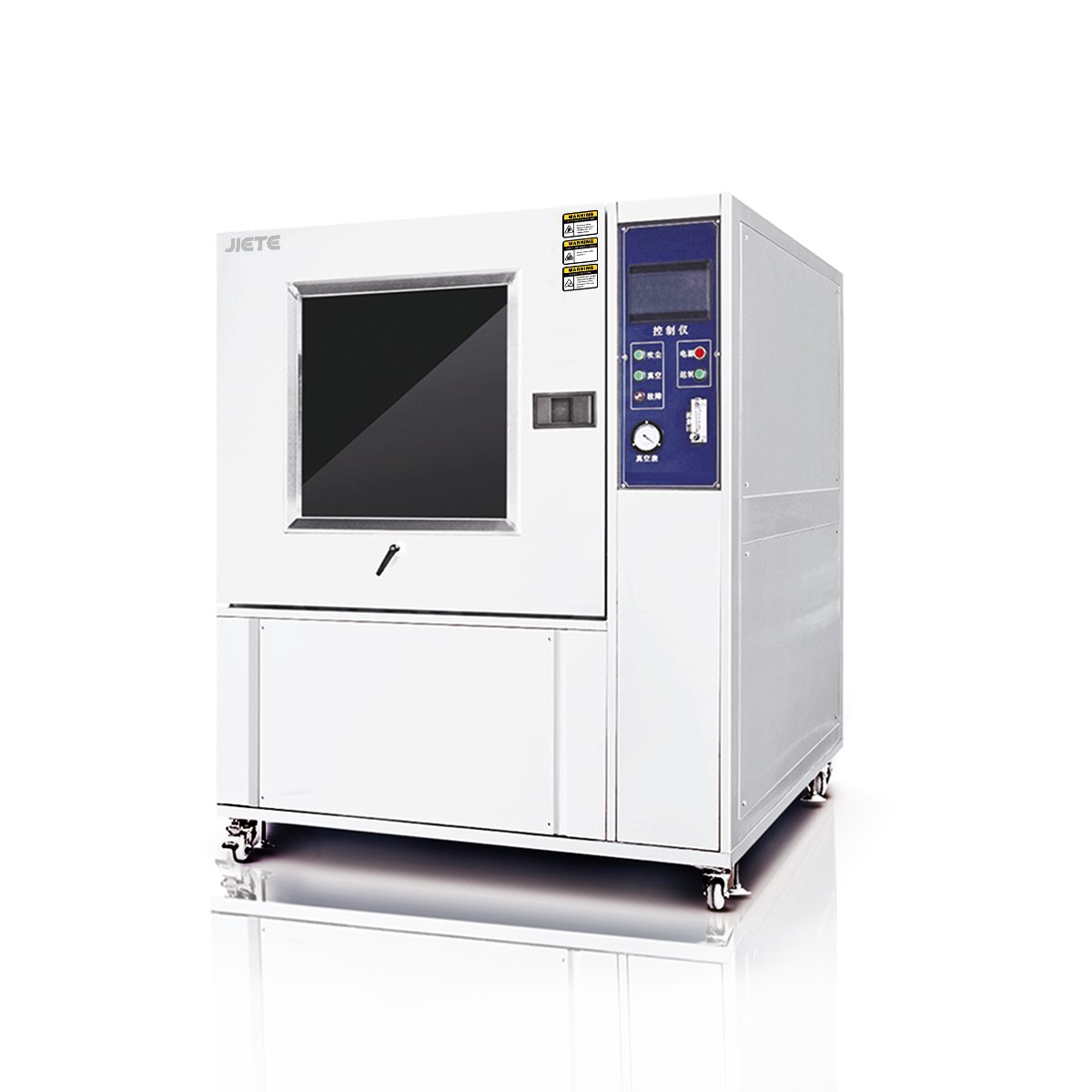

Overview

The Dust Test Chamber is specifically engineered to simulate harsh desert and dusty environments, making it ideal for evaluating the sealing performance and dust resistance of automotive components, electronics, and industrial equipment. It complies with IP5X and IP6X standards, offering controlled dust flow, adjustable vacuum suction, and programmable test cycles to ensure accurate and repeatable test results.

Features:

Simulates sand and dust environments to evaluate product resistance to dust intrusion (IP5X/IP6X).

Equipped with a programmable PLC + touchscreen control system (Siemens brand).

Integrated vacuum suction and circulating dust blowing system.

Stainless steel mica heating sleeve for precise dust heating.

Adjustable dust blowing interval (stop/blow) and cycle time.

High-grade SUS#201 mirror stainless steel inner chamber.

Multiple safety protections: over-temperature, leakage, circuit, instrument protection.

Test duration programmable up to 999 hours.

Detailed Parameter List

| MODEL | JT-SC-216 | JT-SC-512 | JT-SC-1000 | |

| Chamber Design | ||||

| Internal Volume | L | 216 | 512 | 1000 |

| Internal Dimensions (cm) | W | 60 | 80 | 100 |

| H | 60 | 80 | 100 | |

| D | 60 | 80 | 100 | |

| External Dimensions (cm) | W | 90 | 97 | 140 |

| H | 120 | 130 | 150 | |

| D | 165 | 170 | 190 | |

| Experimental Parameters | ||||

| Temperature Range Of Baking Dust | RT+10℃~60℃ | |||

| Fine Dust | Below 75um | |||

| Coarse Dust | Below 150um | |||

| Airflow Velocity | Less than 2m/s | |||

| Dosage Of Talc Powder | 5kg/m³ | |||

| Dust Concentration | 2kg/m ³ (adjustable) | |||

| Air Flow Meter | 1-20L/M digital air flow meter | |||

| Diameter Of Metal Mesh Wire | 50um | |||

| Nominal Spacing Between Lines | Below 75um or 150um | |||

| Hair Drier | All plastic centrifugal fan | |||

| Vacuum Meter | 0~-10KPa | |||

| Power Supply And Connection (Subject To Actual Usage Configuration) | ||||

| Power Supply | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ | |

| Maximum Power | KW | 3 | 3 | 3 |

| Environmental Temperature/Humidity For Use | Temperature 15 ℃~35 ℃ Relative temperature 25%~75% RH Atmospheric pressure 86~106KPa | |||

| System Components | ||||

| Material Science | Outer Box Material | SUS201 or cold rolled plate baking paint | ||

| Inner Box Material | SUS # 201 stainless steel mirror panel | |||

| Control System | PLC controller+touch screen intelligent control system (Siemens brand) | |||

| Vacuum System | Pressure regulating valve, suction nozzle, pressure regulating three piece set, connecting pipe, vacuum pump | |||

| Dust Heating System | Stainless steel mica heating sleeve | |||

| Basic Structure | Composed of a test chamber, vacuum suction port, circulating dust blowing device, vacuum suction system, flow valve, heating system, protective sun screen, etc | |||

| Controller Function | Dust blowing time (stop, blow) h/m/s adjustable | |||

| Cycle period: arbitrarily adjustable | ||||

| Pre set test time: 0s to 999h99m99s, adjustable at any time | ||||

| Power on method: disconnect connect disconnect | ||||

| Security Protection System | Line sequence protection, leakage protection, over temperature protection, abnormal protection, instrument over temperature protection | |||