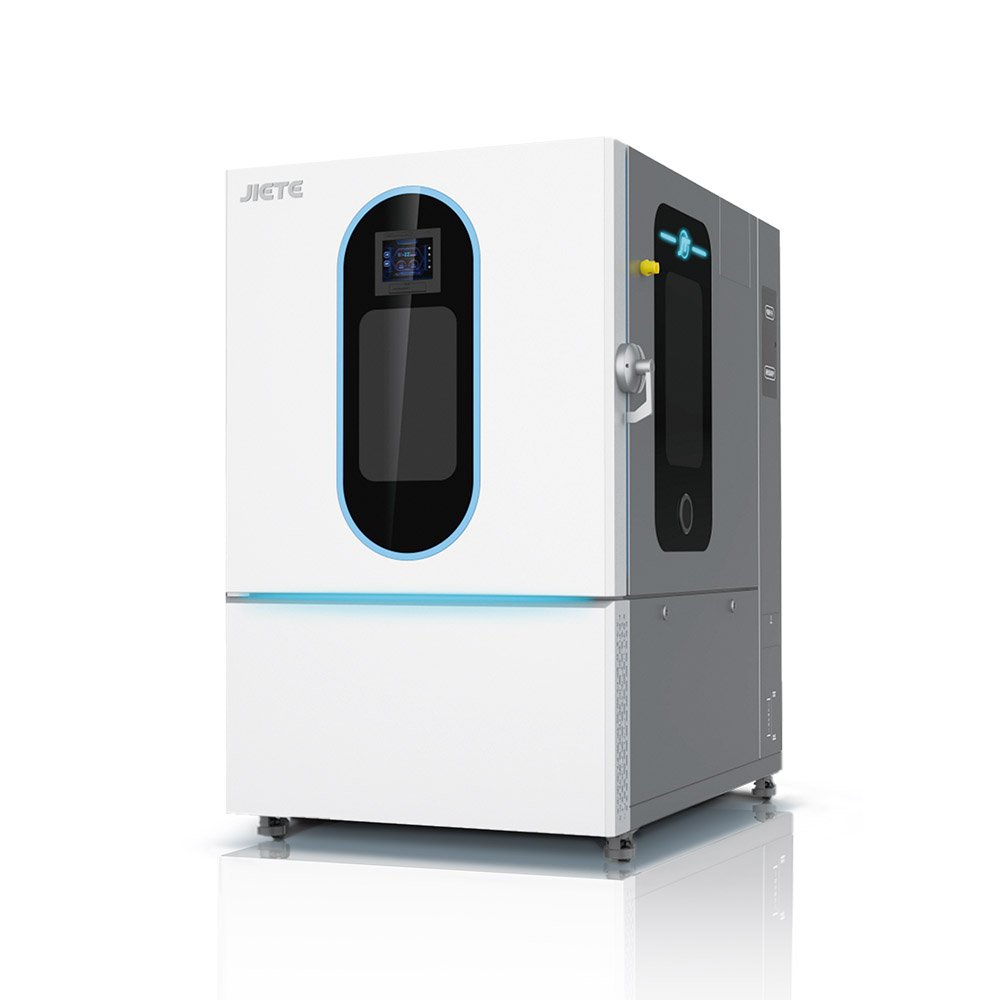

Overview

Our Low Temperature & Humidity Chamber is designed to simulate harsh environmental conditions for testing the durability and performance of products and materials under extreme temperature and humidity conditions. This chamber is ideal for testing a wide range of products, including electronics, automotive parts, medical devices, and packaging materials. The chamber provides precise control over both temperature and humidity, ensuring accurate and reliable test results for your products. With an innovative design and cutting-edge technology, it helps manufacturers meet global quality standards and improve product development cycles.Features

- Wide Temperature Range: Capable of reaching temperatures as low as -70°C, allowing for comprehensive testing of products in extreme cold environments.

- Precise Humidity Control: Equipped with advanced humidity control systems that provide an adjustable humidity range from 20% to 98% RH, ensuring accurate and consistent environmental conditions for testing.

- Uniform Temperature Distribution: The chamber features optimized airflow and temperature control to ensure uniform temperature distribution across all test samples, reducing testing variability and improving result consistency.

- Advanced User Interface: A user-friendly touchscreen interface with intuitive controls for easy setup, monitoring, and adjustment of test parameters. The chamber allows for both manual and programmable operation modes to meet various testing requirements.

- Energy Efficient: Engineered with energy-saving technology, our chamber minimizes power consumption while maintaining high performance and accuracy, making it a cost-effective solution for long-term testing.

- Safety Features: Equipped with multiple safety mechanisms, including over-temperature protection, power failure protection, and automatic shut-off functions, ensuring the safety of both the equipment and test specimens.

- Durable and Reliable: Constructed from high-quality, corrosion-resistant materials to withstand repeated use and provide long-lasting performance. The chamber’s rugged design ensures reliability even under demanding test conditions.

- Flexible Configuration Options: Available in a variety of sizes and custom configurations, enabling users to tailor the chamber to their specific testing needs. Non-standard specifications and chamber modifications can be accommodated upon request.

Detailed Parameter List

| MODEL | JTH-380L-70-CPLH | JTH-380L-70-CPLH | JTH-380L-70-CPLH | JTH-380L-70-CPLH | JTH-380L-70-CPLH | |

| Chamber Design | ||||||

| Internal Volume | L | 380 | 480 | 600 | 800 | 1000 |

| Internal Dimensions (cm) | W | 80 | 100 | 100 | 100 | 100 |

| H | 80 | 80 | 100 | 100 | 100 | |

| D | 60 | 60 | 60 | 80 | 100 | |

| External Dimensions (cm) | W | 100 | 120 | 120 | 120 | 120 |

| H | 177 | 177 | 197 | 197 | 197 | |

| D | 192 | 192 | 192 | 211 | 231 | |

| Temperature Test Parameters | ||||||

| Minimum Temperature | °C | -70 | -70 | -70 | -70 | -70 |

| Maximum Temperature | °C | 150 | 150 | 150 | 150 | 150 |

| Heating Rate | °C/min | 1~3°C/min ; Accept non-standard customization | ||||

| Cooling Rate | °C/min | 0.7~1°C/min; Accept non-standard customization | ||||

| Temperature Fluctuation | °C | After stabilization, ≤± 0.5 °C | ||||

| Temperature Uniformity | °C | 2 | 2 | 2 | 2 | 2 |

| Temperature Deviation | °C | ±2 | ±2 | ±2 | ±2 | ±2 |

| Humidity Test Parameters | ||||||

| Humidity Range | %RH | 5% ~ 98%RH | ||||

| Humidity Deviation | %RH | A)>75%RH:≤+2,-3%RH,B)<75%RH:≤±5%RH | ||||

| Humidity Fluctuation | %RH | ±3 | ±3 | ±3 | ±3 | ±3 |

| Humidity Uniformity | %RH | 5 | ||||

| Power supply and Connection (Subject To Actual Usage Configuration) | ||||||

| Power Supply | V/Hz | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ |

| Maximum Current | A | 10.0 | 6 | 6.1 | 7.3 | 8.8 |

| Maximum Power | KW | 2 | 4 | 4 | 4.8 | 5.8 |

| Control Mode | PID+SSR | |||||

| Environmental Temperature/Humidity For Use | Air cooling:+5 °C~+28 °C/≤ 85% RH; Water cooling: water temperature 10 °C~28 °C, water pressure: 0.25~0.4MPa | |||||

| System Components | ||||||

| Material Science | Shell Material | Electrolytic board baking paint | ||||

| Inner Liner Material | SUS # 316 stainless steel plate | |||||

| Thermal Insulation Material | Rigid polyurethane foam | |||||

| Refrigeration System | Cooling Method | Mechanical compression single-stage/cascade refrigeration; A air-cooled/W water-cooled | ||||

| Compressor | French Taikang/Emerson Valley Wheel Fully Dense Vortex Compressor | |||||

| Refrigerant | Non fluorinated environmentally friendly refrigerant HFC R404A R23 | |||||

| Humidification Water Supply | Water Supply Method | Pressure stabilizing pump | ||||

| Water Tank Capacity | 15L | |||||

| Heater | Nickel chromium wire heater | |||||

| Circulating Fan | Centrifugal fan | |||||

| Door Observation Window | The single door is equipped with a 3-layer vacuum glass observation window for heat and sweat prevention; Door frame electric heating (automatic adjustment) anti frost and anti condensation device | |||||

| Temperature Sensor | Platinum resistance PT100 | |||||

| Humidity Controller | Dry wet bulb sensor | |||||

| Temperature/Humidity Controller | High precision resistive touch screen, can be controlled by a USB external mouse; Historical curve record, PID+SSR/SCR automatic bidirectional synchronous output | |||||

| Noise | ≤ 70db (A-level sound level) | |||||

| Enclosure | Stainless steel test rack with 2 layers; Two types of soft plugs with a diameter of 100mm for testing holes, one on each side; One 15L water tank | |||||