Overview

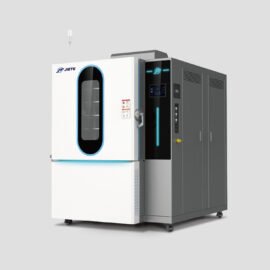

The High-Temperature Precision Oven is a high-performance environmental testing chamber designed to operate at temperatures ranging from ambient to 300°C, with customization options available for even higher temperatures. It is ideal for applications requiring precise temperature control in industries such as electronics, automotive, aerospace, and materials testing. This oven is particularly effective for processes like curing, aging, drying, and heat treatment, offering exceptional reliability and accuracy under elevated temperature conditions.

Features

- Wide Temperature Range: The oven operates from ambient temperature up to 300°C, with customization options for higher temperature ranges, making it versatile for various high-temperature testing applications.

- High-Precision Temperature Control: Advanced temperature control systems ensure stable and accurate temperature settings, with minimal deviation, for precise and repeatable test results.

- Efficient Heating System: Equipped with high-efficiency heating elements, the oven rapidly reaches the desired temperature, reducing testing time and improving overall productivity.

- Uniform Temperature Distribution: A well-designed air circulation system guarantees even heat distribution throughout the chamber, ensuring consistent testing conditions.

- Customizable Features: The oven can be customized to meet specific requirements, such as increased temperature capacity, additional testing capabilities, or specialized chamber materials.

- User-Friendly Interface: The intuitive control panel and touch-screen interface allow for easy setup, programming, and monitoring of testing parameters.

- Energy-Efficient Operation: Built-in energy-saving features reduce overall power consumption while maintaining optimal performance and temperature stability.

- Safety Features: Comprehensive safety mechanisms, including over-temperature protection, alarm systems, and automatic shutdown, ensure secure operation under all conditions.

- Versatile Application: Perfect for testing a wide range of materials and components in industries requiring high-temperature environments, such as electronics, automotive, and manufacturing.

Detailed Parameter List

| MODEL | JPO-72-200/300 | JPO-150-200/300 | JPO-216-200/300 | JPO-480-200/300 | JPO-1000-200/300 | |

| Chamber Design | ||||||

| Internal Volume | L | 72 | 150 | 216 | 480 | 1000 |

| Internal Dimensions (cm) | W | 45 | 50 | 60 | 80 | 100 |

| H | 40 | 60 | 60 | 100 | 100 | |

| D | 40 | 50 | 60 | 60 | 100 | |

| External Dimensions (cm) | W | 80 | 86 | 96 | 116 | 136 |

| H | 122 | 142 | 142 | 182 | 182 | |

| D | 64 | 74 | 84 | 84 | 124 | |

| Temperature Test Parameters | ||||||

| Temperature Range | °C | RT+10℃~200℃/300℃ | ||||

| Analysis Accuracy | °C | 0.1 | ||||

| Heating Rate | °C/min | From room temperature to 100 degrees Celsius, 15 minutes; From room temperature to 200 degrees Celsius, 30 minutes | ||||

| Single Point Volatility | °C | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| Distribution Bias | °C | ±2.0 | ||||

| Power supply and Connection (Subject To Actual Usage Configuration) | ||||||

| Power Supply | V/Hz | AC220V 50HZ | AC220V 50HZ | AC220V 50HZ | AC380V 50HZ | AC380V 50HZ |

| Maximum Current | A | 11.4 | 13.7 | 15.9 | 13.7 | 18.2 |

| Maximum Power | KW | 2.5 | 3 | 3.5 | 9 | 12 |

| Control Mode | PID+SSR | |||||

| System Components | ||||||

| Material Science | Shell Material | Electrolytic board baking paint | ||||

| Inner Liner Material | Heat resistant and cold resistant stainless steel plate | |||||

| Thermal Insulation Material | High density insulation rock wool and insulation device, insulation thickness 100mm | |||||

| Airtight Material | Airtight device resistant to -60 to 500 ℃ | |||||

| Heating System | Imported high-temperature heating wire is used for rapid heating | |||||

| Circulating Fan | Adopting multi blade centrifugal circulating fans, strengthening the axis iron rotating blades, and evenly distributing the temperature field effect | |||||

| Door Observation Window | Single door opening | |||||

| Temperature Sensor | Platinum resistance PT100 | |||||

| Temperature Controller | Korean imported temperature controller/digital setting/PID automatic adjustment/deviation correction/timing function | |||||

| Enclosure | A. Non fuse switch, over temperature protection switch B. Indicator lights and instructions for various actions C. Equipped with exhaust vent device D. Lead hole: Φ 50mm/100mm test hole and rubber plug | |||||