Overview

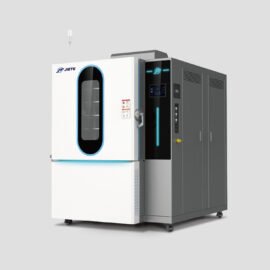

The Three-in-One Comprehensive Test Chamber is a state-of-the-art, multifunctional testing system that seamlessly integrates temperature, humidity, and vibration testing capabilities within a single unit. Engineered to enhance testing efficiency and accuracy, it caters to a wide range of industries including electronics, automotive, pharmaceuticals, and materials science.

Features

- Multi-Functional Testing Capabilities

- Integrates temperature, humidity, and vibration testing in one chamber.

- Allows for simultaneous or sequential testing to simulate real-world conditions.

- Precision Environmental Control

- Advanced control systems provide precise regulation of temperature and humidity levels.

- Stable and uniform environmental conditions ensure consistency and repeatability in test results.

- User-Friendly Interface

- Intuitive touch-screen display for easy navigation and operation.

- Programmable settings and customizable test profiles to accommodate various testing requirements.

- Robust and Durable Construction

- High-quality materials and engineering ensure long-term reliability and resistance to wear.

- Sealed design minimizes contamination and maintains internal conditions effectively.

- Comprehensive Data Logging and Analysis

- Built-in data acquisition systems record key parameters in real-time.

- Connectivity options for seamless integration with external software for detailed analysis and reporting.

- Enhanced Safety Features

- Equipped with over-temperature protection, pressure relief valves, and emergency shut-off mechanisms.

- Compliance with international safety standards to protect both users and equipment.

- Energy Efficiency

- Designed with energy-saving components to reduce power consumption without compromising performance.

- Environmentally friendly operation contributes to lower operational costs.

- Compact and Space-Saving Design

- Optimized footprint allows for installation in laboratories and industrial settings with limited space.

- Modular design options for easy expansion or integration into existing systems.

- Versatile Application Range

- Suitable for testing a wide variety of products, including electronic devices, automotive parts, pharmaceuticals, and materials.

- Ideal for stress testing, lifecycle analysis, and environmental simulation.

- Compliance with International Standards

- Meets or exceeds industry standards such as ISO, ASTM, and IEC for testing equipment.

- Ensures that test results are globally recognized and trusted.

- Low Maintenance Requirements

- Easy access to internal components for routine maintenance and servicing.

- Minimal downtime with durable parts and reliable performance.

- Advanced Vibration Testing Capabilities

- Simulates real-world vibrational stresses to assess product durability and performance.

- Adjustable frequency and amplitude settings to replicate various environmental conditions.

Detailed Parameter List

| MODEL | JSZH-SZXL-40/70-XCPA/W | ||||||

| Chamber Design | |||||||

| Internal Volume | L | 1150 | 2000 | 3000 | 4000 | 6000 | 8000 |

| Internal Dimensions (cm) | W | 120 | 120 | 140 | 160 | 190 | 200 |

| H | 80 | 120 | 135 | 160 | 160 | 200 | |

| D | 120 | 140 | 160 | 180 | 220 | 230 | |

| External Dimensions (cm) | W | 161 | 212 | 230 | 230 | 190 | 240/306 |

| H | 213 | 215 | 200 | 228 | 230 | 260/290 | |

| D | 412 | 450 | 535 | 535 | 550 | 662/550 | |

| Vibration Table Surface Size | CM | 60*60 | 80*80 | 100*100 | 120*120 | 150*150 | 160*160 |

| Temperature Test Parameters | |||||||

| Temperature Range | °C | -70°C~+150°C | |||||

| Humidity Range | %RH | 20%(10%)~98%RH | |||||

| Heating Rate | °C/min | 1 ℃~5 ℃ (10 ℃, 15 ℃, 20 ℃, 25 ℃)/min Overall average or linear | |||||

| Cooling Rate | °C/min | 1 ℃~5 ℃ (10 ℃, 15 ℃, 20 ℃, 25 ℃)/min Overall average or linear | |||||

| Temperature Fluctuation | °C | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 |

| Temperature Uniformity | °C | 2 | 2 | 2 | 2 | 2 | 2 |

| Temperature Deviation | °C | ±2.0 | ±2.0 | ±2.0 | ±2.0 | ±2.0 | ±2.0 |

| Humidity Deviation | %RH | ||||||

| Power Supply and Connection | |||||||

| Power Supply | V/Hz | AC 380V±10%; 50Hz±2Hz; Three phase four wire+ground wire | |||||

| Control Mode | PID+SSR | ||||||

| Environmental Temperature/Humidity For Use | Air cooling:+5 ℃~+35 ℃/≤ 85% RH; Water cooling: water temperature 10 ℃~28 ℃, water pressure: 0.25~0.4MPa | ||||||

| System Components | |||||||

| Material Science | Shell Material | Cold rolled steel plate electrostatic double-sided spray coating | |||||

| Inner Liner Material | SUS # 304 stainless steel plate | ||||||

| Thermal Insulation Material | 120mm rigid polyurethane foam insulation layer | ||||||

| Refrigeration System | Cooling Method | Mechanical binary freezing method (air-cooled/water-cooled) | |||||

| Compressor | Full density vortex compressor | ||||||

| Refrigerant | Environmentally friendly refrigerant | ||||||

| Heating System | Finned nickel chromium alloy electric heating tube | ||||||

| Circulating Fan | Multi blade centrifugal circulating fan, reinforced shaft and high and low temperature resistant rotating blades made of aluminum alloy | ||||||

| Door Observation Window | Coated heating anti frost central control glass observation window | ||||||

| Temperature Sensor | Platinum resistance PT100 | ||||||

| Humidity Sensor | Electronic sensor | ||||||

| Temperature/Humidity Controller | Touch screen 10.0-inch color LCD touch control screen | ||||||

| Noise | dB(A) | ≤ 70dB (A-level sound level) | |||||

| Enclosure | 2 Φ 100mm operating holes (with cover and soft plug), lighting fixtures, air pressure balancing device, etc | ||||||