|

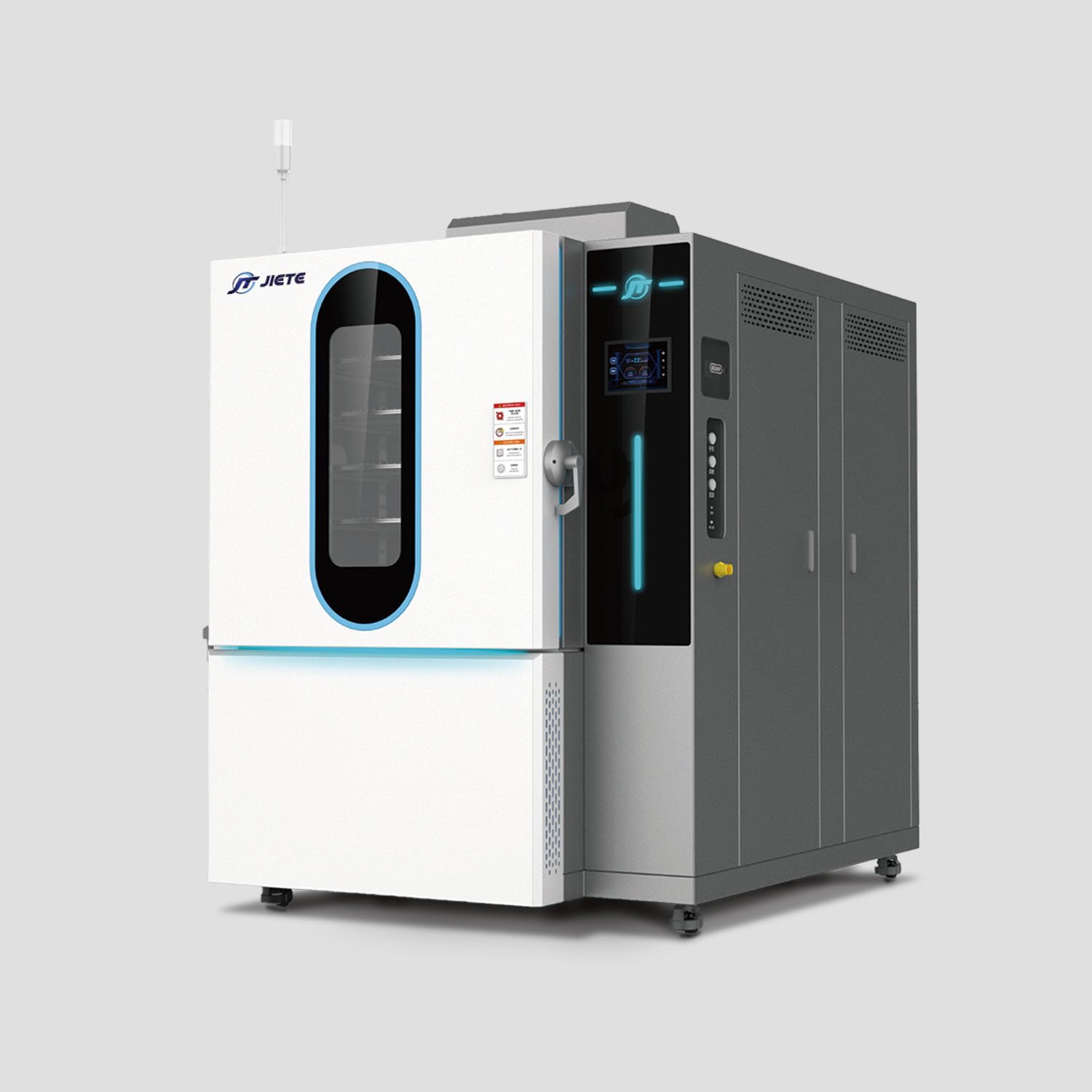

MODEL |

JTK-XL-70-XCPA/W |

JTK-HXL-70-XCPA/W |

|

Chamber Design |

|

Internal

Volume |

L |

150 |

270 |

400 |

500 |

800 |

1000 |

270 |

500 |

1000 |

|

Internal

Dimensions (cm) |

W |

50 |

60 |

80 |

100 |

100 |

100 |

60 |

100 |

100 |

|

H |

75 |

90 |

90 |

100 |

100 |

100 |

90 |

100 |

100 |

|

D |

40 |

50 |

56 |

80 |

80 |

100 |

50 |

80 |

100 |

|

External

Dimensions (cm) |

W |

100 |

114 |

140 |

150 |

150 |

150 |

114 |

150 |

150 |

|

H |

180 |

223 |

223 |

228 |

228 |

228 |

223 |

228 |

228 |

|

D |

149 |

170 |

183 |

201 |

201 |

221 |

170 |

201 |

221 |

|

Temperature Test Parameters |

|

Minimum Temperature |

°C |

-70 |

-70 |

-70 |

-70 |

-70 |

-70 |

-70 |

-70 |

-70 |

|

Maximum Temperature |

°C |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

|

Rapid Temperature Range |

°C |

-40℃~+100℃ |

|

Heating Rate |

°C/min |

Linear adjustable options: 5 °C/min, 10 °C/min, 15 °C/min, 20 °C/min, 25 °C/min |

|

Cooling Rate |

°C/min |

Linear adjustable options: 5°C/min, 10 °C/min, 15°C/min, 20 °C/min, 25 °C/min |

|

Temperature Fluctuation |

°C |

After stabilization, ≤± 0.5 ℃ |

|

Temperature Uniformity |

°C |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

Temperature Deviation |

°C |

±2.0 |

±2.0 |

±2.0 |

±2.0 |

±2.0 |

±2.0 |

±2.0 |

±2.0 |

±2.0 |

|

Humidity Test Parameters |

|

Humidity Range |

%RH |

/ |

20% ~98% |

|

Relative Humidity Deviation |

%RH |

±3 |

±3 |

±3 |

±3 |

±3 |

±3 |

± 3% RH (>75% RH unloaded); ± 5% RH (≤ 75% RH unloaded) |

|

Power Supply And Connection |

|

Rated Voltage |

V/Hz |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

|

Maximum Current (Taking 20 ℃/min As An Example) |

A |

56.2 |

68.4 |

77.5 |

86.6 |

106.4 |

114 |

71.4 |

89.7 |

119.4 |

|

Maximum Power (Taking 20 ℃/min As An Example) |

KW |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

|

Control Mode |

PID+SCR |

PID+SCR |

|

Environmental Temperature/Humidity For Use |

A air-cooled (ambient temperature: 5 ℃~28 ℃)/W water-cooled (water temperature: 10 ℃~28 ℃, water pressure: 0.25~0.4MPa) |

|

System Components |

|

Material Science |

Shell Material |

Electrolytic board baking paint, thickness 1.5mm |

|

Inner Liner Material |

SUS # 304 stainless steel plate |

|

Thermal Insulation Material |

High density rock wool+high temperature resistant high-density polyurethane foam |

|

Refrigeration System |

Cooling Method |

Mechanical compression cascade refrigeration; A air-cooled/W water-cooled |

|

Compressor |

Emerson Valley Wheel Fully Dense Vortex Compressor+German Bitzer |

|

Refrigerant |

Non fluorinated environmentally friendly refrigerant HFC R404A R23 |

|

Humidification Water Supply |

Water Supply Method |

/ |

Automatic hydration |

|

Water Tank Capacity |

/ |

15L |

15L |

15L |

|

Heater |

Nickel chromium wire heater |

|

Circulating Fan |

Centrifugal fan |

|

Door Observation Window |

The single door is equipped with a 3-layer vacuum glass observation window for heat and sweat prevention;

Door frame electric heating (automatic adjustment) anti frost and anti condensation device |

|

Temperature Sensor |

Platinum resistance PT100 |

|

Humidity Sensor |

/ |

Electronic humidity sensor |

|

Temperature/Humidity Controller |

High precision resistive touch screen, can be controlled by a USB external mouse; Historical curve record, PID+SSR/SCR automatic bidirectional synchronous output |

|

Noise |

dB(A) |

< 75dB from 1 meter away |

|

Enclosure |

Stainless steel test rack with 2 layers; 100mm diameter test hole soft plug type 1; User manual, technical data |

|

Enclosure |

2 stainless steel shelves; The box is equipped with a plastic pull-out 15L water tank in one piece, with a diameter of 50mm/100mm, 2 pieces, and one on each side of the box; Action indicator light |